The University’s Kent and Medway Engineering, Design, Growth and Enterprise (EDGE) Hub team has been responding to the Covid-19 crisis by developing solutions for the urgent production of essential personal protective equipment (PPE) to support nurses, GPs, care-workers, parole officers, and other key frontline workers in the fight against the virus.

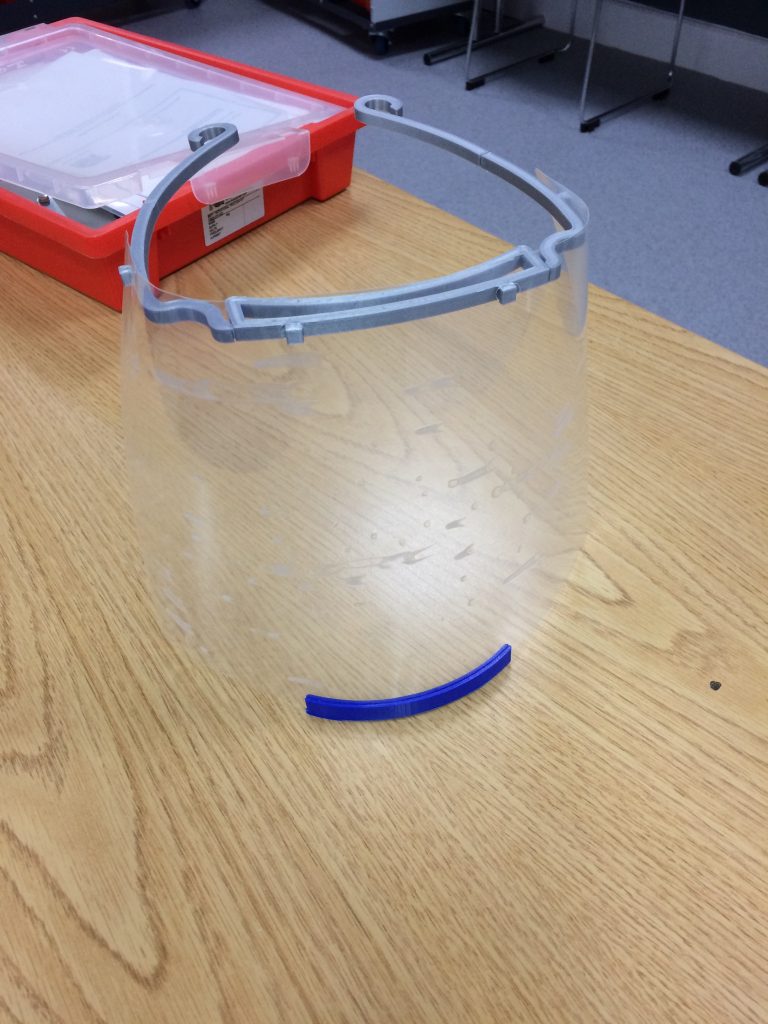

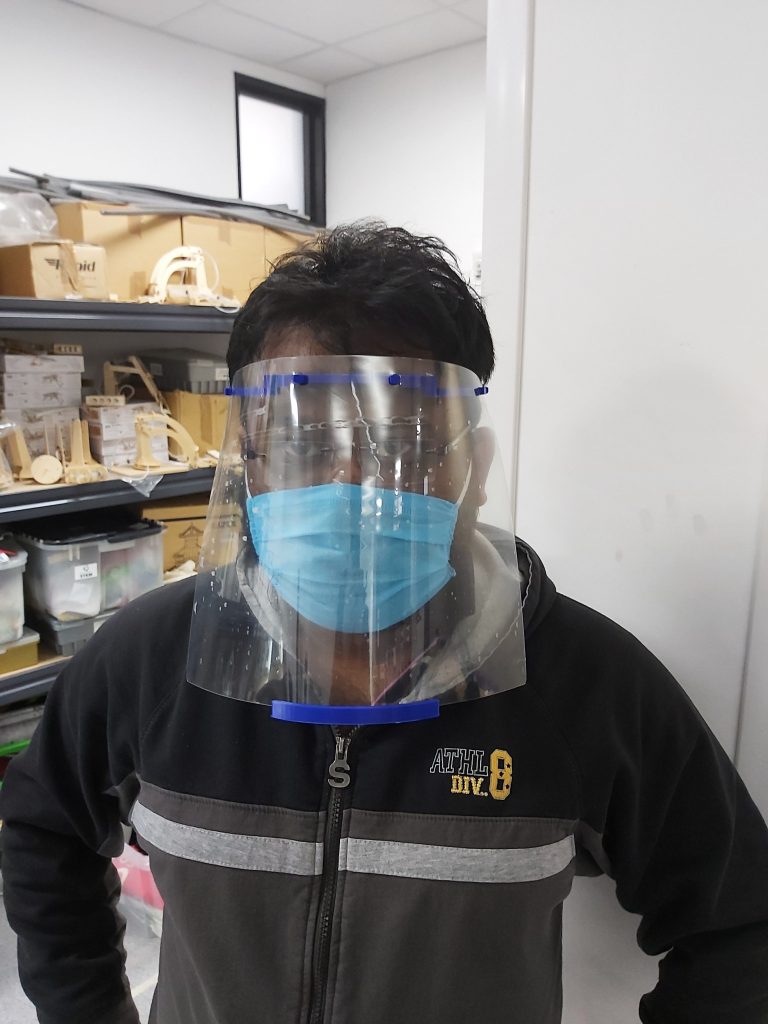

Dr Salman Saeidlou, Senior Lecturer in Mechanical/Material Engineering and Soumya Manna, Lecturer in Design Engineering, have been applying a CDIO (Conceive, Design, Implement, Operate) approach to a prototype three-part open source PPE visor design that would enable the small 3D printer community to contribute to the nationwide efforts. The designs have been given to 3DCrowd UK, a community of 3D printer owners who are volunteering to print these face shields to trial.

The visors cover the face with a transparent shield, protecting the wearer from potentially infectious droplets being absorbed through the face and allowing them to continue crucial face-to-face work, such as healthcare and essential services.

Over 9,000 visors have been requested across Kent, and originally only eight volunteers were actively producing the visors at an average production rate of seven and half per day. Through the University’s STEM Hub, the Engineering team has called out to all the STEM contacts across the South East with small and large 3D printers to assist the collective effort in producing the visors.

This resulted in 199 volunteers registered across Kent, including Chatham and Clarendon Grammar School who are now producing over 10,000 per week.

The school designed, with medics, a mass manufacture solution using PET sheets made from recycled bottles. They have setup a GoFundMe page to support the school’s production of PET sheets.

Dr Anne Nortcliffe, Head of the School of Engineering, Technology and Design, is supporting the co-ordination of visors produced by volunteers across East Kent for the local community in Kent and further afield across the UK. She is also informing local and national community producers on good health and safe practices of manufacturing the visors for medical use during the Covid-19 pandemic.

“If you or your business needs facial visors, if you have a 3D printer, or if wish to financially support this national effort, then please visit the 3DCrowd UK website to support ’The Big Print’ campaign.

“Alternatively, if you have manufacturing capabilities using laser cutting machines or have injection moulding capabilities, please get in touch with me (anne.nortcliffe@canterbury.ac.uk), as we have been contributing to the mass visor manufacturing engineering solutions developed with colleagues at the University of Swansea and the University of Sheffield and local teaching hospitals.”

Dr Nortcliffe

Canterbury Christ Church University’s EDGE Hub follows the CDIO model for engineering education, which was developed by Massachusetts Institute of Technology (MIT) and takes an innovative approach to problem-solving, preparing the next generation of engineers to create solutions to critical, real-world issues.

Engineering, Technology and Design

Engineering, Technology and Design Gareth Ward

Gareth Ward 1449

1449